Nuclear Medicine Essentials Buying Guide

Expert guidance and practical tips for optimizing nuclear medicine safety, comfort, quality control, and compliance.

Why Nuclear Medicine Essentials Matter

Nuclear medicine teams balance patient care with complex radiation safety practices, rigorous quality control, and strict regulatory oversight. Each procedure requires precision, safety, and a steady focus on compliance.Drawing on three decades of expertise, Marketlab delivers carefully curated accessories and supplies to help nuclear medicine teams thrive in a high-stakes, high-standards environment.

How to Use This Guide

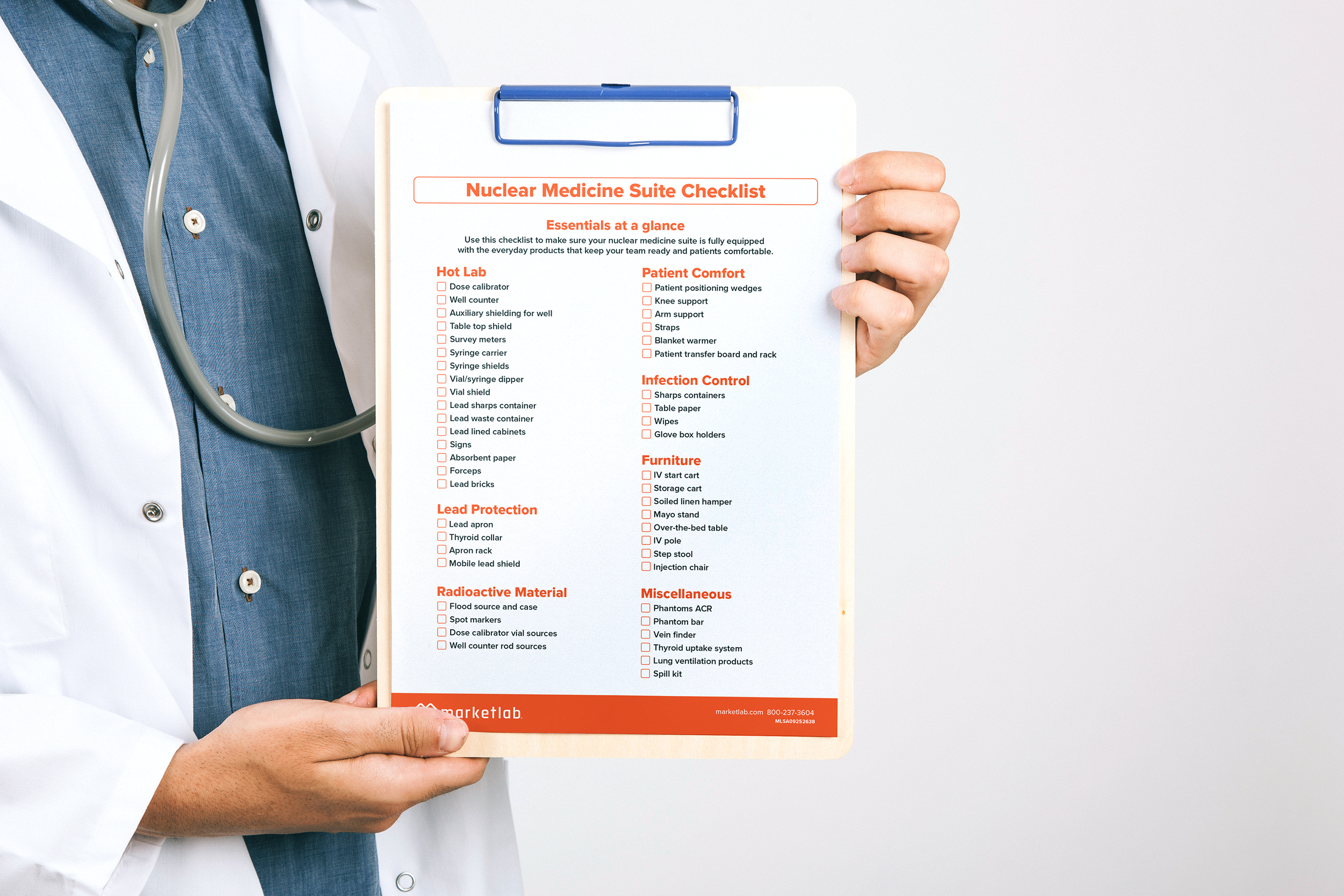

We’ve organized key nuclear medicine insights into four categories to help you make purchase decisions with confidence.

Safety: Safeguard staff and patients with best practices and tools that deliver radiation controls and protection.

Patient Comfort: Improve the patient experience and image quality with comfort accessories that reduce anxiety and support stillness.

Workflow: Strengthen daily operations by streamlining preparation and building consistent quality control practices.

Regulatory & Compliance: Demonstrate adherence to industry standards and maintain accreditation through solid, everyday practices.

Safety

Keeping Radiation Risks Under Control

Radiation safety is at the heart of nuclear medicine. Every task in the hot lab and exam room — from drawing doses to transporting syringes and managing waste — carries exposure risk. Effective shielding, vigilant monitoring, and clear protocols transform those risks into controlled, repeatable processes that protect patients and staff alike.

Focus Areas

Equip your hot lab with the right barriers. Choose L-blocks, lead glass shields, and cabinetry matched to your isotope mix and daily volume.

Build daily monitoring into routine workflows, using survey meters and dosimetry badges to confirm exposure stays within ALARA limits.

Place spill kits and labeled waste containers in every hot lab and injection area for immediate response.

Marketlab’s Top Radiation Safety Solutions

Did you know?

Over 40 million diagnostic nuclear medicine procedures are performed globally each year, with ongoing advances designed to improve both safety and patient experience.*

*Advances in Nuclear Medicine Mean Patient Protection Needs Strengthening, IAEA Department of Nuclear Safety and Security, 2025.

Patient Comfort

Reducing Anxiety, Supporting Stillness

Nuclear medicine exams often involve long waits after injection, followed by scans that require patients to remain still for extended periods. Anxiety about radiation, physical discomfort, and difficulty holding still can all compromise image quality.

Comfort-first positioning and safe immobilization reduce movement, ease stress, and make lengthy procedures more tolerable.

Focus Areas

Provide reclining chairs, table pads, and wedges that minimize strain during injection, uptake, and imaging.

Stabilize patients with foam supports and immobilization aids that cushion rather than constrict, reducing motion artifacts without adding pressure.

Use warmed blankets and comfort accessories to ease anxiety and help patients remain still throughout long procedures.

Marketlab’s Top Comfort Solutions

Did you know?

Research shows that non-pharmacologic interventions (e.g., comfortable positioning, communication, and environment modifications) are effective at reducing anxiety and improving patient comfort during nuclear imaging.*

*M. Champendal, et. al., A scoping review of person-centred care strategies used in diagnostic Nuclear Medicine. Radiography, Volume 30, Issue 2, 2024.

Workflow

Balancing Accuracy and Efficiency

Nuclear medicine workflows hinge on both productivity and precision. Hot labs must be organized for safe dose prep, and imaging systems need daily constancy checks with sealed sources or phantoms to confirm performance. When quality control (QC) tasks are routine and staff are trained to carry them out consistently, exams stay on schedule and results remain dependable.

Focus Areas

Organize hot labs for fast and safe access to shielding, sealed sources, and carriers so prep and transport happen smoothly and predictably.

Make QC the first task of each shift, with constant checks for dose calibrators, uniformity floods for cameras, and sealed source verifications to catch issues before the first patient arrives.

Reinforce staff competency with ongoing training and refreshers to ensure consistent QC routines, handling practices, and dependable throughput.

Marketlab’s Top Quality Control Solutions

Did you know?

All ACR Nuclear Medicine accredited facilities must maintain a documented QC program and comply with the minimum frequencies of testing standards outlined in the 2024 ACR Nuclear Medicine Quality Control Manual.

Regulatory & Compliance

Industry Standards in Action

Compliance in nuclear medicine reaches into nearly every task: labeling and posting radiation areas, preparing and transporting radiopharmaceuticals, testing sealed sources, and documenting QC routines.

Federal rules, state oversight, and accreditation bodies all expect facilities to show these safeguards in action, not just on paper. Embedding those expectations into routine tasks makes compliance less of a hurdle and more of a habit.

Focus Areas

Mark and monitor radiation areas visibly so postings, access controls, and delivery checks demonstrate compliance during daily operations, not just inspections.

Apply USP <825> in ways that simplify work, including using pre-labeled containers and dedicated storage that make safe handling second nature.

Keep QC logs integrated with workflow so that calibrator, sealed source, and system checks are documented automatically, and survey readiness is always current.

Marketlab’s Top Compliance Solutions

Key Compliance Checkpoints

Radiation Controls & Handling

Post Radiation Areas and RAM rooms; survey Class 7 packages at receipt (NRC Part 20).

Apply USP <825> standards for labeling, beyond-use dating, storage, and waste.

Ensure DOT Class 7 compliance for packaging, labeling, and shipping documentation.

Confirm license scope with your state program if operating in an Agreement State; align RAM oversight with NRC or state rules

Instrumentation & QC

Maintain dose calibrator records: daily constancy, quarterly linearity, annual accuracy/geometry.

Perform generator breakthrough testing for Mo-99/Tc-99m and Rb-82.

Complete sealed-source inventories and leak tests every six months.

Capture gamma camera/SPECT QC results (daily peaking, uniformity, periodic phantoms).

Keep PET/CT QC logs current per manufacturer and professional guidance.

Apply decay-in-storage procedures for ≤120-day half-life nuclides; log disposal surveys.

People & Process

Maintain staff competency files with training and annual policy reviews.

Track corrective actions with written responses to findings.

Nuclear Medicine Essentials in Action

Nuclear medicine teams succeed on discipline: clear radiation controls, consistent quality control, and patient-centered comfort that help teams capture critical diagnostic images without delays or do-overs.

The right accessories and supplies don’t just support these standards – they make precision and safety achievable in every procedure.

Connect with a Marketlab expert at 800-237-3604 or service@marketlab.com